What Is The Difference Between Web And Sheetfed Printing?

Introduction to web and sheetfed printing

Web and sheetfed printing are both excellent ways to print your product.

At Warners, we run both types of machine in-house and are excellently placed to offer advice on the pros and cons of each method.

What is Sheetfed Printing?

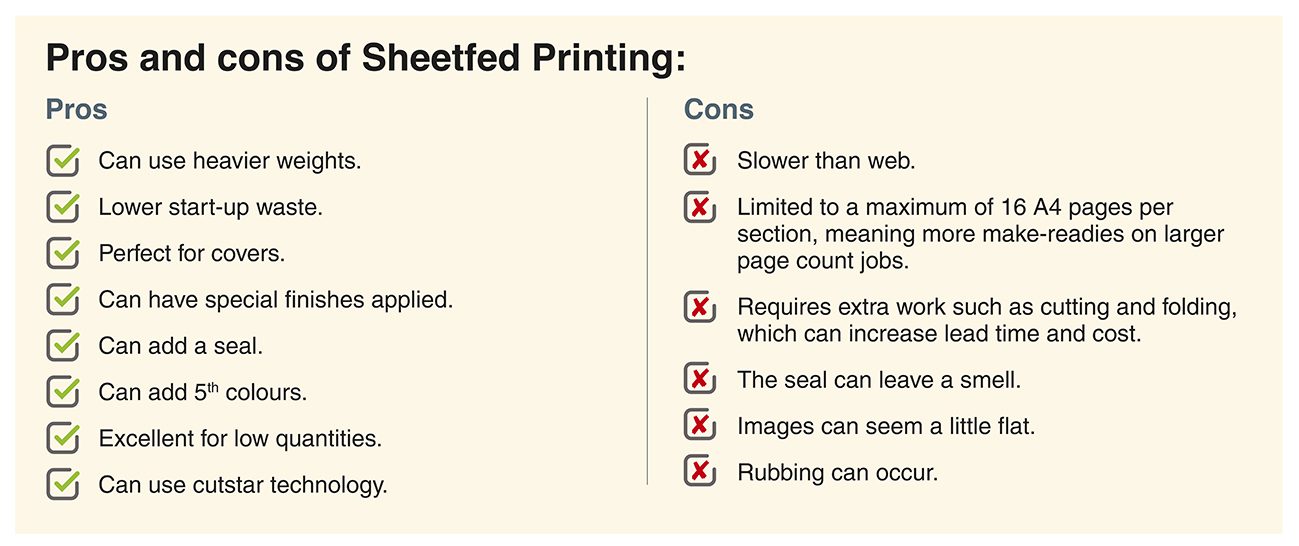

Sheetfed printing is a very common method in the UK, and it is one that we use.

As the name suggests the paper passes through the press as an individual sheet. Depending on the size of the press, each sheet can have up to 16 A4 pages on it. The upper side of each sheet has ink applied for each of the four colours (CMYK). After this first pass, the half-printed sheets are flipped over and then reloaded onto the press to have the lower side printed. Some sheetfed printing presses can print both sides of the sheet in a single pass. This is thanks to a process called perfecting (not to be confused with perfect binding!). A perfecting press usually has between 8 and 10 ink units. The sheet is printed with CMYK on one side before it is flipped over in the middle of the press to have the lower side of the sheet then printed CMYK.

Depending on the press and the inks used there may be a drying period required before the sheets can be prepared for finishing. If the ink is not UV and not dried with UV lamps, then a very fine powder is applied to each sheet to prevent them from sticking together while the ink dries over a few hours.

Before the print can be collated and prepared for the binding process, sheetfed work will have to be cut and folded separately, which requires additional time and costs compared to web printing.

At Warners, we use sheetfed presses to compliment our web machines, printing high-quality covers and special options such as gatefolds.

What is Web Printing?

We are web printing specialists with decades of experience, and it is our passion!

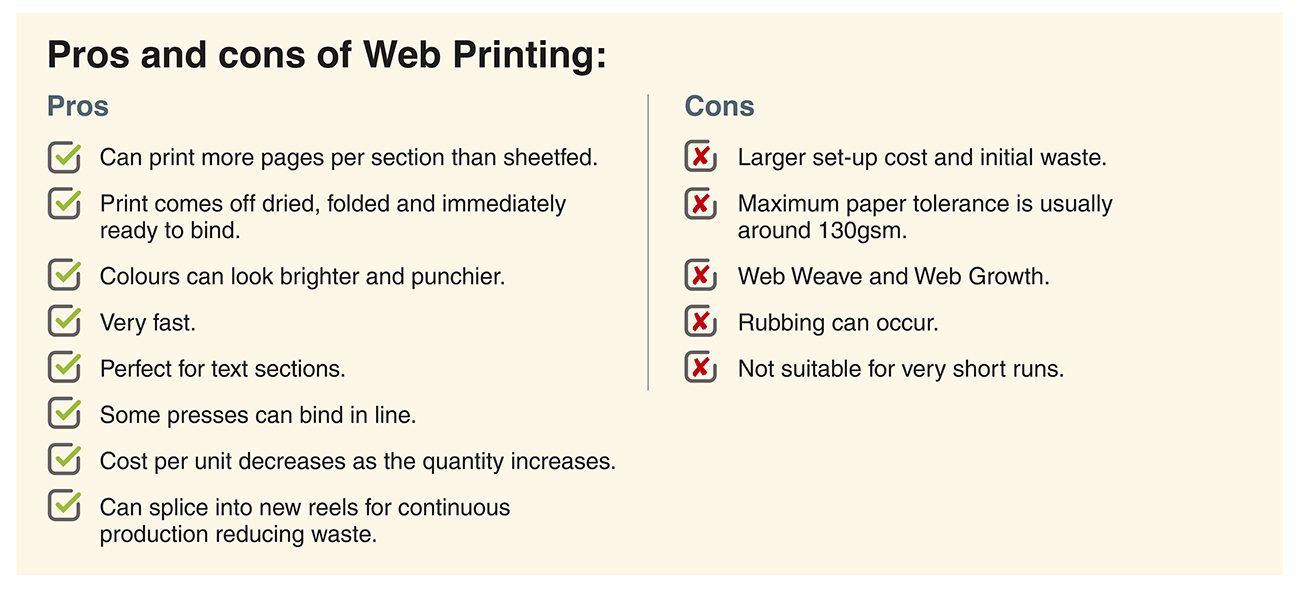

Web printing, like sheetfed, is a four-colour process. The word web refers to the paper used, which is delivered in reels, which are huge rolls many kilometres long! Web paper is taken through the press in a continuous ribbon. It is printed, dried and folded in line and ready for finishing in one pass on the press. A web press can also print more pages on each section than a sheetfed press. Most web presses are either 16 or 32-page machines, but there are some presses that can print up to 96 pages of A4 on a single pass!

How this happens is that the paper is taken from a paper reel and fed into the press. The paper is fed through the middle of the four ink units. In the units, ink is applied to both the top and bottom of the ribbon simultaneously, and each colour is added one after another. Once the ink has been applied, the paper is taken through the drier, where heat is used to dry the ink. Once through the dryer, the paper passes through several rollers, getting progressively cooler before being taken up to the folder. The ribbon is then folded down several times and cut to form the appropriate section before following a conveyor belt to be stacked for transportation to the bindery.

Which is better between web and sheetfed printing?

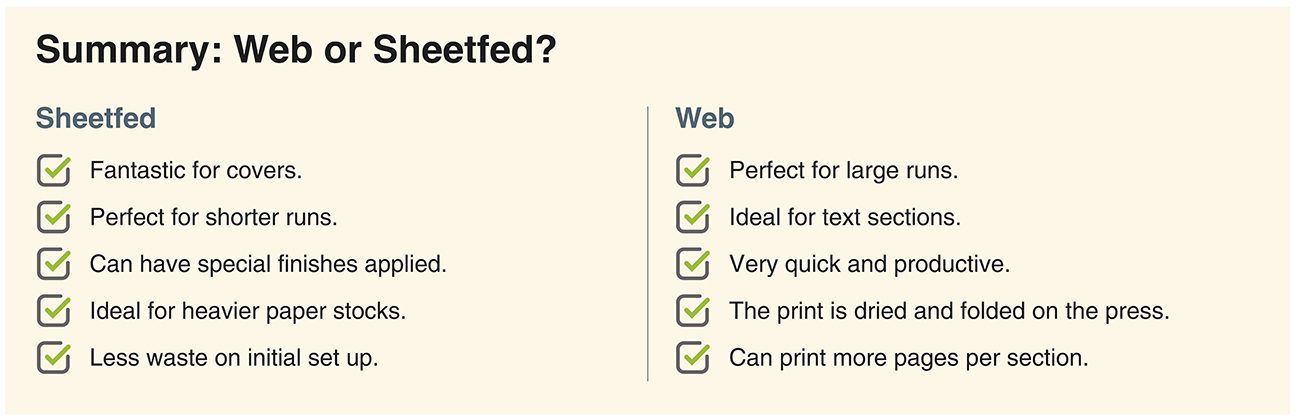

Both Web and Sheetfed printing are excellent options for customers looking to print. As you have read from above, the best choice for a customer will be based on their specification.

Each method is used to produce high-quality print depending on the requirements of each customer. As we use both methods in-house, we provide a more rounded perspective and offer customers the choice where the specifications allow. Most customers tend to use a mixture of the two methods, having a sheetfed cover and the text printed, allowing them the best of both worlds.

Whichever method you pick with us, all of our presses have closed-loop colour systems and all the benefits of recent technology to reduce waste, improve quality and provide competitive pricing.

Further Help

Warners offer a free no obligation Consultation Service to help advise customers who are unsure which method is best for them. We are always happy to help and are here to work with you to get the best result for your plan, specification, and budget.

Request Your Free Quote

Getting a quote for your print couldn't be easier! You can also choose how you want to communicate with us. Fill out the your specification with an email we can contact, and we can take care of the rest! We can also advise you on cost-saving considerations or suggest more efficient methods of production.