Print Terms Glossary

If you are new to print it can seem like the industry is speaking in another language! To be fair sometimes we are, as there is such a large amount of specialist terminology that gets thrown about. Most of the time though, it is easy to explain what we mean and to make things even easier we have prepared this glossary of print terms to help.

Within the glossary you will find common terms, problems, technical language and easy-to-understand definitions

Print Terms

BPOP

BPOP stands for “Bulk Packed on Pallets” which is the standard packaging option where bundles of printed products are stacked on a pallet up to a certain weight or height. The finished pallet will then be wrapped in shrink wrap with corner protectors ready for delivery.

Crows Feet

Crows feet is creasing that can be found around the folds on a printed job, this is usually because of heavier paper stock.

Cut off

This term relates to paper that is used from reels. As the paper passes through a press, the reel is cut into sheets, either before the ink is applied as is the case on a sheet-fed machine, or after the ink is applied as on a web press. The cut off is the length of the sheet that is cut from the reel of paper.

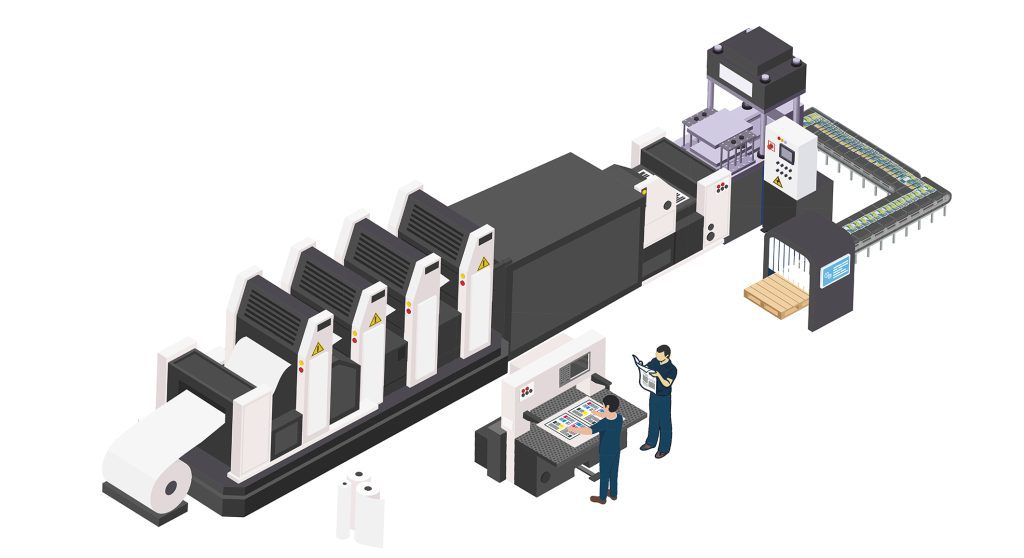

Cutstar

Sheet-fed presses require the paper to go through the machines as a sheet; however, a special addition can be added to convert reels to sheets. A cutstar is essentially a small reel stand that can be wheeled in and out of position as needed. The reel stand contains a spinning blade that cuts the reel to the appropriate length so that it feeds sheets into the press. This option is popular as it can save on waste and be more cost effective however it is limited by what size and weight of paper can be obtained in reels.

Densities

Colour is subjective as everyone’s eyes are different. The print industry works to an industry-set level of densities that printers adhere to on each job. The density refers to how much of each ink colour is applied to the sheet within an area. If the density readings are within the parameters set by the industry, a job is deemed to be commercially acceptable in terms of colour.

Dot gain

Printing is a bit of an optical illusion. Small dots of ink are applied to the paper to create the images desired. Over time, the dots can grow on press as they are squished by the rollers, making images darker than intended but would still be within density. This is a normal and natural part of the printing process, and most of the time, it is not noticeable except under magnification. Dot gain is the difference in size between the larger dot and the original intended dot. Regular checks and changes are scheduled on our presses to reduce and minimise the effects of Dot gain.

Ex works

You might see the phrase “Ex Works” on a quote. On our quotes, this means that the pallet is available to collect from our premises or will need to be delivered for an additional charge based on the location.

Fluting

Fluting is the wavy lines on the paper that appear after printing when the substrate has become fully saturated with ink. In extreme occurrences, these can result in cracks in the paper but are unfortunately unavoidable for certain papers with heavy ink coverage.

Ghosting

This is the appearance of a faint image repeated from another area of the sheet. It can be caused by poor roller settings (inkers and dampers). Some substrates are more prone to this, and it can be unavoidable.

GSM

The standard UK measurement for paper is grams per square metre or GSM. Printers use this measurement to provide customers with a reference of the qualities of their job. Samples are often available to be sent to the customer. For reference, the average paper for a home printer, for example, would be 80gsm.

Hickie

Foreign body on printing plate or blanket resulting in a small halo-like shape in an image on the sheet. The missing colour in ring of halo determines the unit location of the foreign body.

Imposition

Imposition is a very common print term. An Imposition is an arrangement (or grid) of pages, positioned and orientated so that, after printing, when the sheet is folded, the pages run sequentially and are backed up (correct front with correct back) as intended. An imposition is usually comprised of 16 A4 pages. Depending on the press size and type, the page size, the binding method, and the page orientation, there will be a unique imposition for each. Sometimes, in other processes, an imposition is called a form or a section.

Mechanical paper

Mechanical papers are made by grinding fibres to create the pulp generally using stone, which makes for a less refined product than papers that have been made with chemical pulp involving which involves bleaching etc.

Office copies

These are the copies of a print run that will be supplied to the customer directly to their offices. Sometimes a job would be sent to a depot or distribution hub and the office copies allow a customer to assess the quality of the job.

Overnight pallet services

An option for customer delivery. An overnight pallet service is where a courier on the pallet network collects a job from the printer and it will then be taken to an appropriate depot to be loaded onto a lorry and delivered usually the next working day anywhere in the mainland UK. Once the pallet has left the printer, there is no way to track it or make any changes.

Perfect binding

A method of binding in which hot melt glue is used to stick the sections of pages together. A perfect bound job requires a spine and is suitable for larger paginations as opposed to saddle-stitched binding.

Plates

A printing plate is a sheet of aluminium with a chemical coating applied to one side. The plate is required in offset printing to attract ink to the correct areas of an impression. Each plate must be thin enough to be wrapped around a cylinder and as a result can be quite fragile and prone to damage if not handled correctly. Each plate can only be used once and is recycled after use.

Press Pass

Sometimes, customers want to see their jobs printed on press. There can be many reasons for this, but the main one is that they want to assess the quality of the job and make live changes to the colour densities. This process of observing the job on the printer is called a press pass.

Proof

A proof is a means of providing a visual representation as to how a page will reproduce on press. They are mainly in the form of “hard” (paper) copies but can also be a “soft” (on-screen) representation. A Proof can be colour and content correct or content correct only. If colour correct, factors including the type of printing substrate (paper) are factored in, giving the proof a more realistic representation of what can be achieved on press. In all cases, ‘data integrity’ is paramount. Otherwise, differences may occur between the proof and the final printed matter.

PUR Binding

PUR (polyurethane reactive) binding is similar to perfect binding in that the page sections are arranged in the same way prior to binding and there is a spine. Instead of a hot melt glue being used to stick all the page sections together a special air cured adhesive is applied. Once this has cured the bind is set forever and is much stronger making PUR perfect for large pagination jobs like catalogues with hundreds of pages.

Register

When printing it is essential that all of the colours line up correctly on the press. This is referred to as register. There is a set of marks on each plate called tick marks that are in place to help operators line up each colour one on top of another. When the register is correct, the tick marks will all line up, presenting a solid black line that will be removed during the final trimming during the binding.

Rubbing

If you looked at paper under a microscope, its surface would not be smooth. Depending on the paper coating and finish there would be some types that are more rough than others. Stocks such as silk, matt and uncoated paper are likely to rub. What happens is that when ink is applied to these areas, the top layer of the ink dries fully, but underneath, there is a reservoir of “wet” ink. when the paper is rubbed, the top layer of ink can break, releasing some of the wet ink below, which causes marks and smudges on the paper. The main way that this phenomenon is reduced is to either seal it on a sheetfed press or to print it on a web press; however, it is impossible to fully prevent this from happening.

Run on & run back

Run-on and run-back costs are a great way for customers to plan and budget for quantity changes from their initial quote. By using the run-on figure they can see what to add to the price for printing a number of extra copies and with the run back they can see what they would save by reducing the quantity.

For example:

A customer has a quote for 10,000 copies that cost £5,000 and a run-on price of £100 per 1000 copies, and a run-back of £90 per 1000 copies.

The cost of increasing the quantity to 12,000 copies would be £5000 + (2×100) = £5,200

The cost of reducing the quantity to 9,000 copies would be £5,000 -£90 = £4,910.

Saddle stitching

A quick, efficient and cost-effective method of binding smaller pagination jobs. A line of wire is passed through the centre sections of a printed product and stitched together. This stitching looks like small staples and there are usually 2 of them for the average job. A unique benefit of this binding is that you can have pull out sections such as posters in the middle that are designed to be removed by the end user.

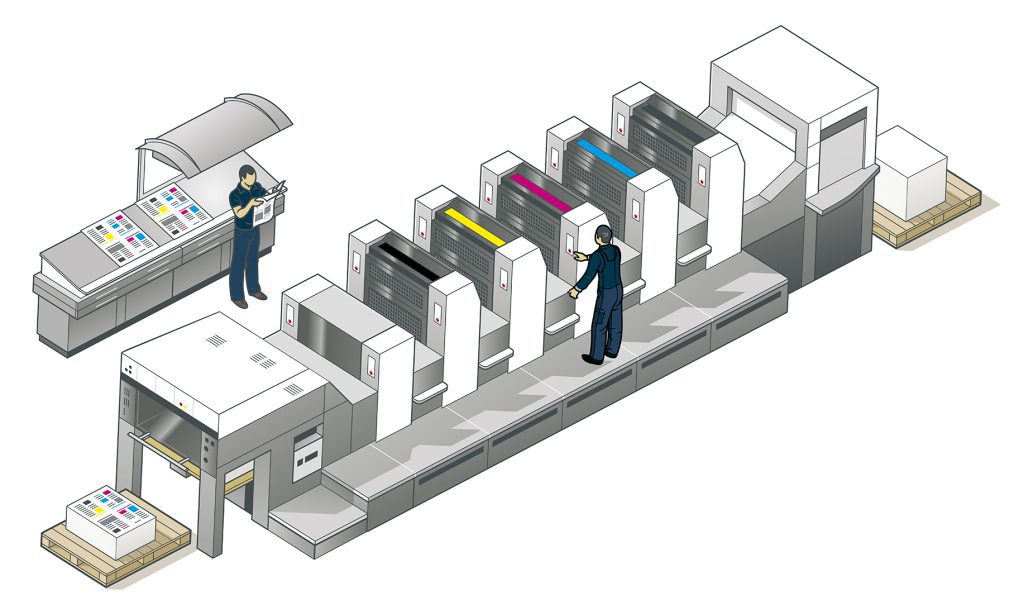

Sheetfed printing

Sheetfed printing is a very common print term which describes a method of printing that takes the paper through the press as an individual sheet. Sheetfed printing is perfect for covers and low run jobs. It is high quality but requires a great deal of additional work such as cutting and folding before it can be bound.

Show through

Show through is where due to the opacity of the paper an image from the reverse side of the page can be seen in normal lighting conditions. As paper grades become lighter the chances of show through tend to increase.

Shrink wrapping

When printed products are finished in the absence of specific packaging instructions, they are usually bulk packed on pallets and have a protective wrap of plastic film wound around them to protect the paper from damage in transit or the weather. The plastic wrap is called shrink wrap. Bundles of products can also be shrink wrapped rather than boxed which also ensures they are protected and waterproof.

Special sized reels

For Web and cutstar printing, reels of paper rather than sheets are used. For the industry, there are common sizes of reels that most printers use that are easy to obtain. In our sector these common sizes are 870mm and 880mm reels as they are perfectly sized for A4 and A5 jobs which are the most common.

If a customer wants a unique-sized job, then they would, depending on the size, either look at ordering a special-sized reel that is calculated precisely for their specification. This special size requires a unique order to be placed at a paper mill that cannot be changed or cancelled once the order is placed. This paper cannot be then used on any other job and would have to be paid for in full by the customer.

These reels can often take 8 weeks, if not longer, to produce.

UCR

AKA Under colour Removal. The process of removing C,M,Y ink out of dark areas (to create black) and replacing these three colours with just black ink. The % of UCR can be adjusted prepress. This is an ink saving adjustment.

Web/Web printing

The print term web printing sometimes simply called web is a type of printing where the paper is taken through the press from a reel in a continuous ribbon. Imagine a kitchen roll with the edge being pulled and unwinding. The benefits of this process are that the paper can be printed on, dried and folded in a single pass and immediately ready to be bound, requiring no additional steps. It is a high-speed process that is perfect for text sections and lighter papers. With this method of production, the cost per unit decreases as the run length increases, making it very popular on mid to high volume products.

Web breaks

When the ribbon of paper on a web press snaps. This can be caused by many factors such as paper quality, ink coverage and press speed. The press operators then have to re-run the paper through the press resulting in lost time and increased waste.

Web growth and wave

Due to the heat drying process in web printing the paper loses its moisture very quickly. This causes the paper to develop a ripple when observed looking down the spine on the upper and lower edge of the printed product. This is called web wave.

In addition, when a web-printed job is bound, and the final cut is made, the edge of the web paper is exposed to the atmosphere. Over the next 24 hours, this exposed edge reabsorbs moisture from the atmosphere and swells out. The result is that the text pages appear fractionally bigger than the cover.

These are both unavoidable parts of the process but can be managed.

Woodfree paper

Woodfree paper is still made of wood. Wood free paper has had its lignin removed which is yellowish in colour and occurs naturally in wood. The lignin is removed by bleaching the paper, which gives it a very white appearance.

Further print terms help

We hope that you found our print glossary helpful! By no means is it an exhaustive list of all things print however it covers most of the common language that is used. We are always on hand to assist with any questions about print and will be adding terms to the list over time.

You can find more information on our YouTube channel or can drop us a line at 01778 391000 or visit our Contact Us page.