Paper Explained

Explaining paper is a common job for a printer! We put together this guide to help our customers make decisions and understand the process more easily.

The material you pick is the most important consideration in printing any magazine, catalogue or brochure. It affects everything from appearance and texture to production method and cost, and it is worth taking some extra time to be sure that you found the right fit for your needs.

All of the papers we source at Warners are from Europe. We have actually been to the mills to see for ourselves how the process works and the environmental management systems at work. What we have learned through our years of experience and working closely with our suppliers has been compiled and summarised for you.

What we are going to cover:

- Appearance and qualities.

- Grades.

- Weights.

- Sheets or reels?

- Sourcing, Certifications and the Environment.

- Special makings and lead times.

Appearance and physical qualities

Paper comes in many different weights, sizes, textures and finishes. Each of these aspects will have an impact on the printed product. Most papers we use in print have a coating applied to them to change their appearance and how the image will appear.

During its making, the paper can have a coating applied to it, and the extent to which determines its finish. If you were to look at uncoated paper under a microscope, it would have a rough texture. The coatings cover the roughness to different extents, which makes the paper smoother and can give a shiny finish.

A term that is often used in print is Calendering. Calendering is where the surface of the paper is rendered less fibrous and smoother by compressing the paper through rollers whilst being exposed to heat. You might hear of some paper being calendered or supercalendered, and this is what is being referred to.

There are four main finishes available for magazines, catalogues and brochures and we have put them in order of coating from the most applied to the least:

Gloss papers

Gloss papers are common choices for magazines, particularly for covers as the shiny finish often helps the print to stand out and make the colours vibrant. There is also no need to seal gloss stocks due to the nature of the finish.

Silk papers

Silk papers are popular, too. They are still quite shiny but not as much as gloss and have a slightly rougher texture. There is usually a need to seal silk papers most especially if printed sheet-fed as the somewhat coarser texture can result in the ink rubbing off the page in a similar way to a newspaper. Most sheetfed printers do this as standard, but it is always good to check! Web presses do not seal these papers due to the print being dried on press however with both methods heavy coverage can still cause rubbing to occur.

Matt papers

Matt papers are also coated but to a lesser extent than a gloss or silk. This would provide a good surface for the ink to adhere to but without making the page shiny. As with silk stocks, you would require a seal to be applied during printing to reduce the chances of rubbing occurring.

Uncoated papers

Uncoated papers are often described as being “earthy”. These papers are without any form of coating and are rough to the touch but are very white in colour. They allow people to write and draw on the surface very easily, so they are perfect for products like activity books. However, the print can often look a little dull/flat on these papers, especially when compared to gloss stocks and uncoated papers need to be sealed on sheetfed presses to prevent rubbing.

Paper Grades

In addition to the coatings of paper, it can be characterised by its grade. The grading provides a guide to what you can expect from the paper for its qualities and likely pricing.

Woodfree

Woodfree is a bit of a confusing name as the paper is still derived from wood and pulp but uses chemical pulp rather than mechanical pulp. The woodfree element refers to the process removing a protein called lignin from the wood. Lignin makes papers more yellowish and its removal leaves a very white bright paper and is usually found in higher grammages and well suited to covers.

Near Woodfree

Near woodfree is generally seen as a very popular grade for its qualities and is a fantastic middle point between Woodfree grades and lighter grades.

Mechanical

Mechanical paper is made from mechanical pulp. Mechanical pulp is made from wood that has first been separated into fibres using mechanical force, pressure and temperature.

Light weight coated (LWC)

As the name would suggest these are very light papers usually weighing 60gsm or less. The coating as mentioned previously is applied to the paper to give a particular finish.

Recycled Paper

Most papers contain a certain percentage of recycled material within them from the pulp fibres as standard, but some are made from 100% recycled material. 100% recycled papers tend to be greyer in appearance than papers that use some virgin fibres in their making. They are also usually slightly rougher as they are not usually coated and can show speckles in the paper, giving an inconsistent appearance.

However, recycled papers generally use much less energy and water in their creation whilst reducing landfill. It is often impossible to source where the original paper used in its creation was sourced from. It is possible, however, to have FSC certifications for mixes for recycled papers.

Holmen has some great articles to help you understand more about what to consider when choosing between virgin material and recycled stocks.

Supercalendered Papers

These light papers have no coating applied to them but as explained earlier go through a process called calendaring which polishes the paper through heat and pressure giving it a shiny finish.

Paper Weights

When talking about paper in the UK we use weight in the form of gsm Grams per Square Metre. The paper weight is a key identifier in selecting the material for your job as it can determine the process used to print and make a massive difference to your overall material and mailing costs.

A good starting point is to think about the paper you get from a home or office printer which tends to be 80gsm in weight and gives you an idea of what you might want to consider asking for.

You can request blank and printed samples of paper from a printer to help you make your decision. If it is not a common stock or a specialist making it may require the printer asking the mill to prepare a sample which may take longer to arrive.

Show Through

Show through is where due to the opacity of the paper an image from the reverse side of the page can be seen in normal lighting conditions. As grades become lighter the chances of show through tend to increase.

Sheets and Reels

Printers, depending on their set-up and machinery, take delivery of their paper in two forms: sheets and reels (rolls). Each has its own benefits and place in production as in simple terms sheetfed presses use sheets and web presses use reels.

Reels are usually cheaper than sheets, and it is possible to buy reels up to 200gsm. This is because the paper then is too thick and heavy to be wrapped around a core. Web presses cannot use sheets because the paper needs to be taken through the machine in a continuous ribbon with no breaks for the process to work.

Our Sheetfed and Web Printing guide provides an excellent resource to understand the process better.

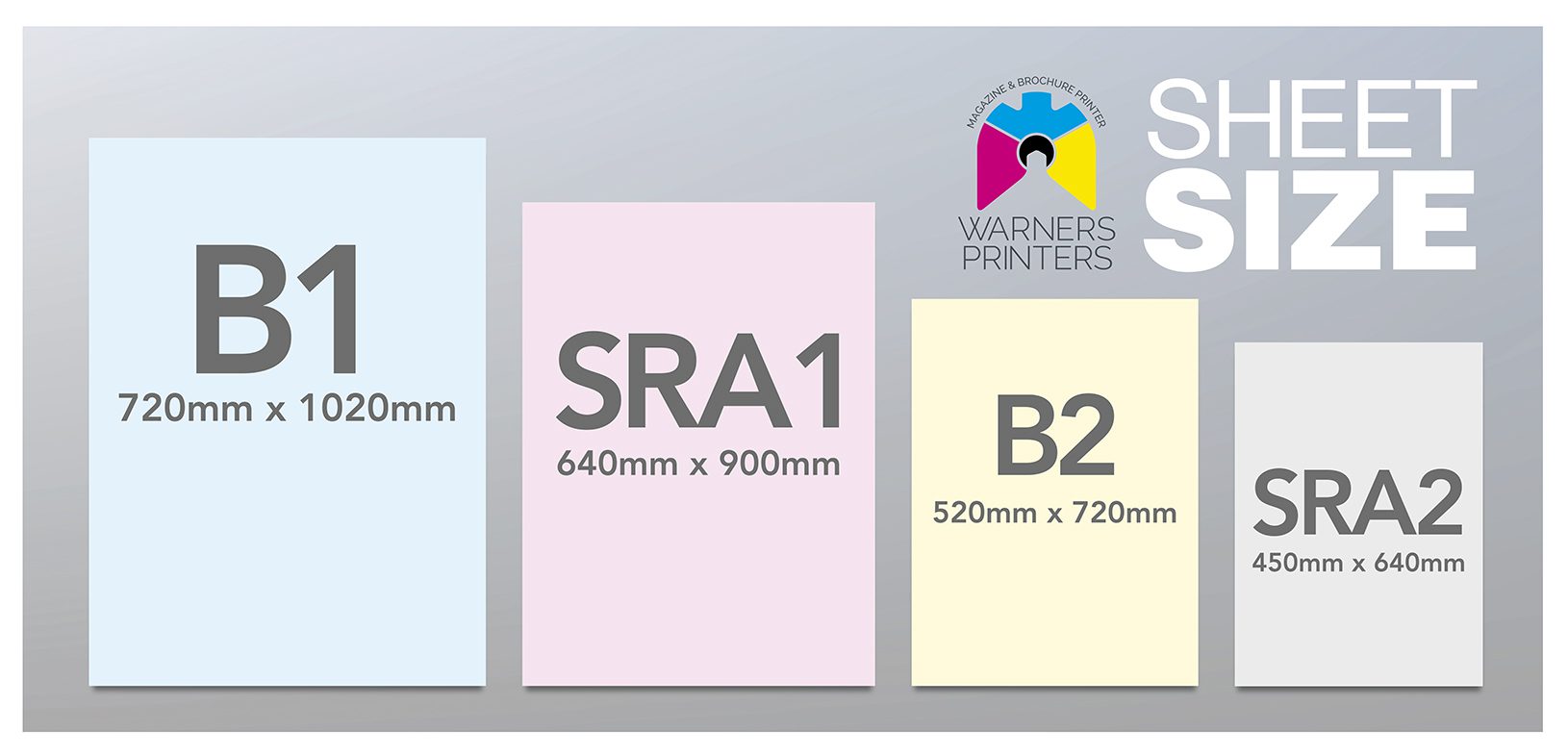

The most common sheet sizes are:

There are standard reel widths that we use are 870mm and 880mm which are easy to source and minimise waste for standard A4 and A5 work. Each reel is barcode-logged and individually trackable. We can identify the product and check for information such as its certifications, weight, product type, length and much more. If there is a problem with the reel, we can work with the mill to identify the item individually and review its making, giving us transparency over the process.

Cutstar

Reels can be more cost-effective than sheets, and it is possible to buy reels of paper that are up to 200 gsm. Many sheetfed printers can use reels thanks to Cutstar technology, allowing customers to take advantage of potential savings if the job specification allows. The Cutstar is a removable attachment on the front of the press that can cut a reel into sheets and feed them directly into the press. We currently utilise this technology on our sheet fed press.

Paper Sourcing, Certifications and the Environment

As responsible companies, we want to know where our materials are sourced and what their carbon footprint is. Papers used by reputable printers come from well-managed forests with appropriate certifications. There is also the option to carbon balance papers which is not always well publicised.

We spoke about recycled papers earlier and it is important to note that paper can only be recycled a few times before the fibres perish. Fresh virgin fibres are required to continue the circular process and ensuring these are harvested from well managed, responsible forests is essential. So how do we do this?

FSC® & PEFC

A good way of understanding where your materials come from is to ask for FSC® or PEFC certified paper which allows you to trace a whole chain of custody.

We are very proud to hold FSC® and PEFC certifications, and you can find out more about them here.

As a customer we will guide you through the process of correctly including logos and all the required steps to certify an FSC® or PEFC product.

Our Suppliers

We are very particular about the paper we buy to make sure it meets all of the obligations set out in our ISO 14001 environmental procedures. Through many years and constant review, we have assembled a list of Key Suppliers that we know and trust to ensure suitable quality levels, environmental responsibility, reliable service and competitive pricing.

Carbon Balanced Papers

For a nominal fee it is also possible to carbon balance papers through organisations such as the World Land Trust. We can guide our customers through the process if this is the direction that they would like to take with their materials.

Special makings and paper order times

As you can imagine, printers use a lot of paper throughout the year and order in huge quantities. We order reels in tons and naturally cannot keep much in stock as they are incredibly bulky. The average 32pp web press can use 3 – 4 tons per hour on average when in production! We keep a calculated amount of our core stocks in-house but manage a constant replenishment system.

Printers tend to manage supply by ordering from the mill in advance and calling off stock from UK wharfs a day or so before we want to begin production. Most of the UK’s graphic papers come from Europe, in particular places like Finland, so time must be factored in as the paper is transported via container shipped to the UK. Normally we would need a few weeks notice on orders however for large quantities or special makings we would require much more notice.

What is a special making?

A special making is where a printer places a unique order with a paper mill for a specification that would fall outside of the usual A4 and A5 sizes. A4 and A5 sizes are commonly able to fit on standard sized reels, in most cases, 870mm and 880mm wide. We can order special sized reels which are made to suit your bespoke page size to minimise wastage. The benefits of specially sized reels are that they reduce spoilage and cost as printers do not have to trim to waste. Because these reels are specially made they often require 4-8 weeks for delivery and minimum order amount, in tons, so it is well worth building this into your plans!

Once an order is placed it is incredibly difficult if not impossible to make changes or cancel it in the run up to the job and the customer would be expected to pay for the material as it is often only usable for them and no one else.

If you are unsure, it is always a good idea to talk to your printer and understand the situation before the order is placed!

Any questions?

It is important to note that while there is a great deal of information here to digest, we are always on hand to help answer your questions. Please contact your account manager, or one of our team at helpdesk@warners.co.uk if you require any further information.